Flake Lining

FGD (Flue Gas Desulfurization) units are designed to minimize the damage on the environment by separating the sulfur dioxide, which is produced as a result of combustion products, from the acidic gas with the help of basic solution.

This process takes place in the absorber unit in the FGD system. It is called an absorber because it absorbs SO2 in the gas produced as a result of the combustion product.

FGD units are generally made of steel, and in some cases they are also manufactured from reinforced concrete.

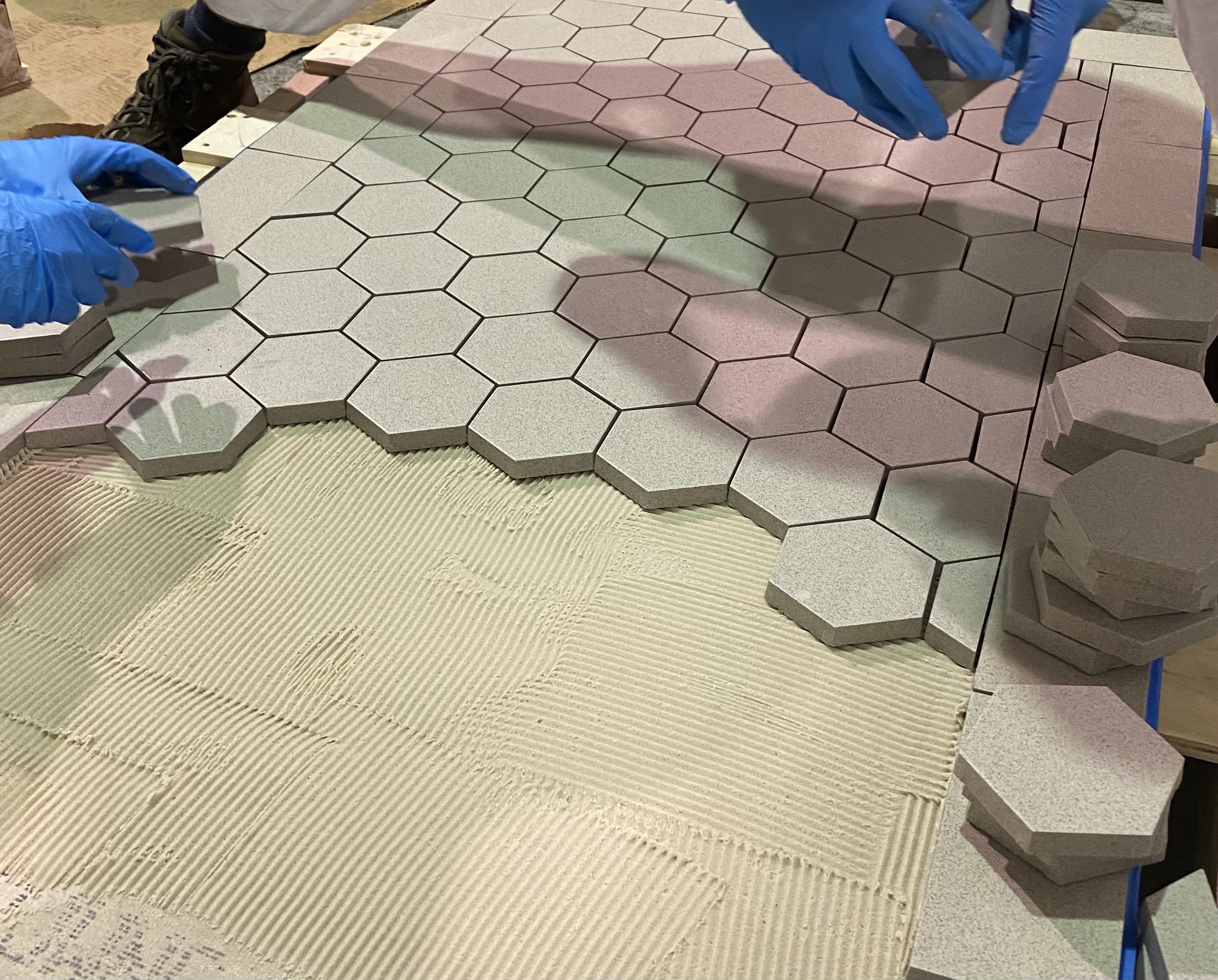

FGD units are one of the most important points of the process in thermal power plants, and flakeline, rubber lining and FRP systems are used as internal coating for protection.

Our expert and professional application team in FGD provides coatings services as;

- Flake Lining in Stack

- Flake Lining and Rubber Lining Inside of the Absorber

- GGH Flake Lining

- Ducts Flake Lining and Rubber Lining

- Flake Lining, Ceramic Epoxy and Rubber Lining for Booster Fan

Designed and developed to protect FGD (Flue Gas Desulfurization) systems, flakeline coatings, thanks to the flake layers they contain, increase impermeability by providing barrier protection and provide a high level of protection in the systems they are applied to.

TECHNON employs NACE certified engineers who are experts in flakeline. In the FGD system; We can answer all your technical questions by providing professional support in the selection and application of Absorber, Ducts, GGH, Booster Fan, Stack Lining. In addition, we provide support to Owner and EPC Contractor companies in terms of specifications.

Flake Lining also provide superior corrosion protection; It is also widely used in concrete areas, acid pools and storage tanks thanks to its against acid, abrasion and corrosion resistance.

Other Products

Rubber Lining

Rubber offers two decisive benefits when it comes to heavy-duty corrosion protection: Being a soft rubber lining, it is flexible and conforms very well to structures that „live...

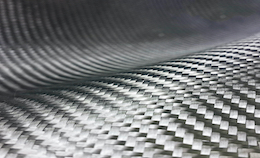

Composite Strengthening Systems

Carbon fiber coating systems, which are used to strengthen and extend the life of buildings, are used in maintenance and repair activities, especially in concrete columns, beams and struc...